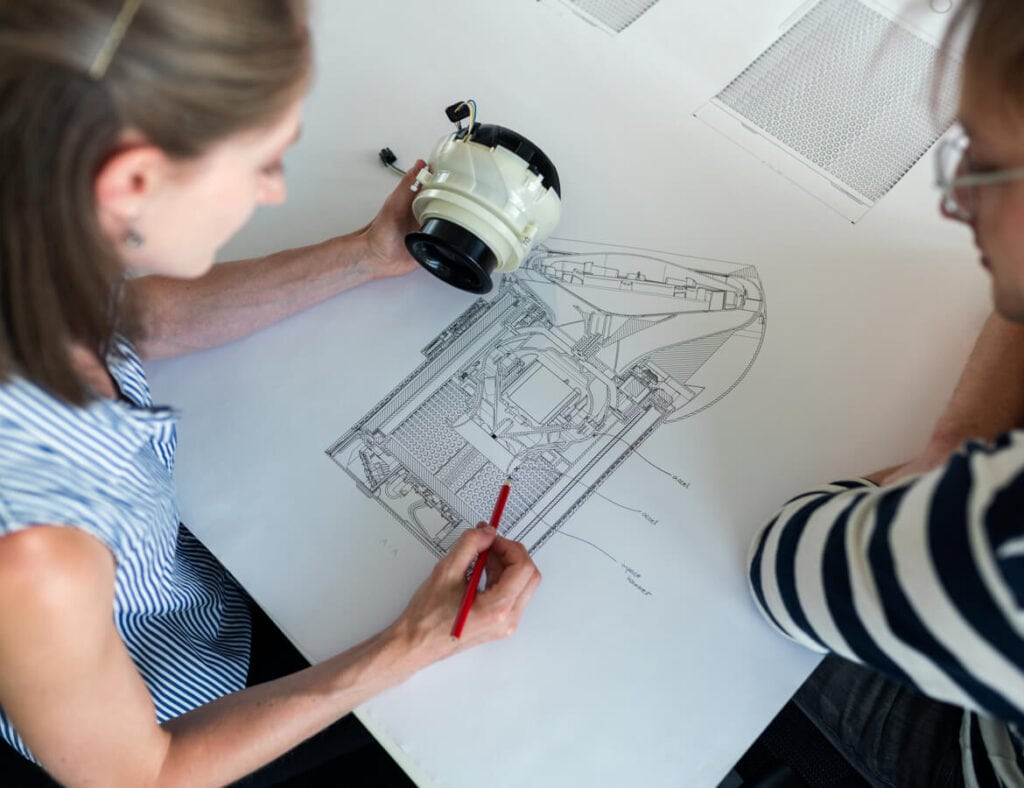

Tooling Design

Our tooling design engineers help customers to develop mould designs that would balance multiple considerations such as aesthetics, materials, and costs to produce optimised parts.

Transforming Designs Into Physical Parts

Designing a product is a complex task involving multiple design considerations in terms of aesthetics, tolerances, materials, costs, manufacturing, assembly, and packaging.

Our tooling designers provide effective and reliable tooling designs that arecost-effective for manufacturing and quality-driven .

Our tooling designers provide effective and reliable tooling designs that are

Services

Our expertise includes:

- 2K Mould Design

- Mouldflow Analysis

- Design for Manufacturing (DFM) Review

- Tool Design Optimisation

- Tool Material Selection

- Cooling Channel Optimisation

- Metal Stamping Tool Design

- Die Design

Why Us

Ergonomics

We take into consideration aesthetics, tolerances, materials, costs, manufacturability while developing mould designs.

Wide Range Of Expertise

We provide multiple services such as mouldflow analysis, 2K moulding design, tool design optimisation and tool material selection.

Cost Effective

Our tooling designers provide

effective and reliable tooling

designs that are cost-effective for

manufacturing and quality-driven.

Build your tool with us

Our tooling designers takes all terms into consideration to provide customers effective and

reliable tooling designs that are cost-effective for manufacturing and quality-driven.

reliable tooling designs that are cost-effective for manufacturing and quality-driven.

Our Satisfied Clients Say It Best

Christian Gaugler

Varta Storage GmbH, Germany

K-One is a well-organized company with an abundance of experience in plastic moulding and metal stamping. They are also experienced in box-build and final assembly with products such as electronic headlamps, floor-care machines, and many more. K-One has an extensive supply chain network which enables them to be competitive and efficient from the supply subsystems to integrated end products.

K-One is a well-organized company with an abundance of experience in plastic moulding and metal stamping. They are also experienced in box-build and final assembly with products such as electronic headlamps, floor-care machines, and many more. K-One has an extensive supply chain network which enables them to be competitive and efficient from the supply subsystems to integrated end products.

Douglas Patterson

Coagusense, Inc., USA

K-One has been our EMS since 2003. It is rare to find a partner that takes proactive measures to continuously improve costs and ensure part quality. K-One has always been by our side and has never taken our business for granted.

K-One has been our EMS since 2003. It is rare to find a partner that takes proactive measures to continuously improve costs and ensure part quality. K-One has always been by our side and has never taken our business for granted.

Peter Johansson

C Technologies AB, Sweden

We have been working together with K-One for many years, and they have always been very supportive and definitely a pleasure to work with. One aspect that stands out with K-One is that they consistently deliver good quality products.

We have been working together with K-One for many years, and they have always been very supportive and definitely a pleasure to work with. One aspect that stands out with K-One is that they consistently deliver good quality products.

Previous slide

Next slide

Talk To Us

Collaborate with us for your next product

HQ/Design Center

Contact Number

+603 7728 1111

Fax

+603 7728 6212

Address

66 & 68 Jalan SS22/21

Damansara Jaya

47400 Petaling Jaya

Selangor

Malaysia

Manufacturing Center

Contact Number

+605 526 9588

Fax

+605 526 9593

Address