Prototype

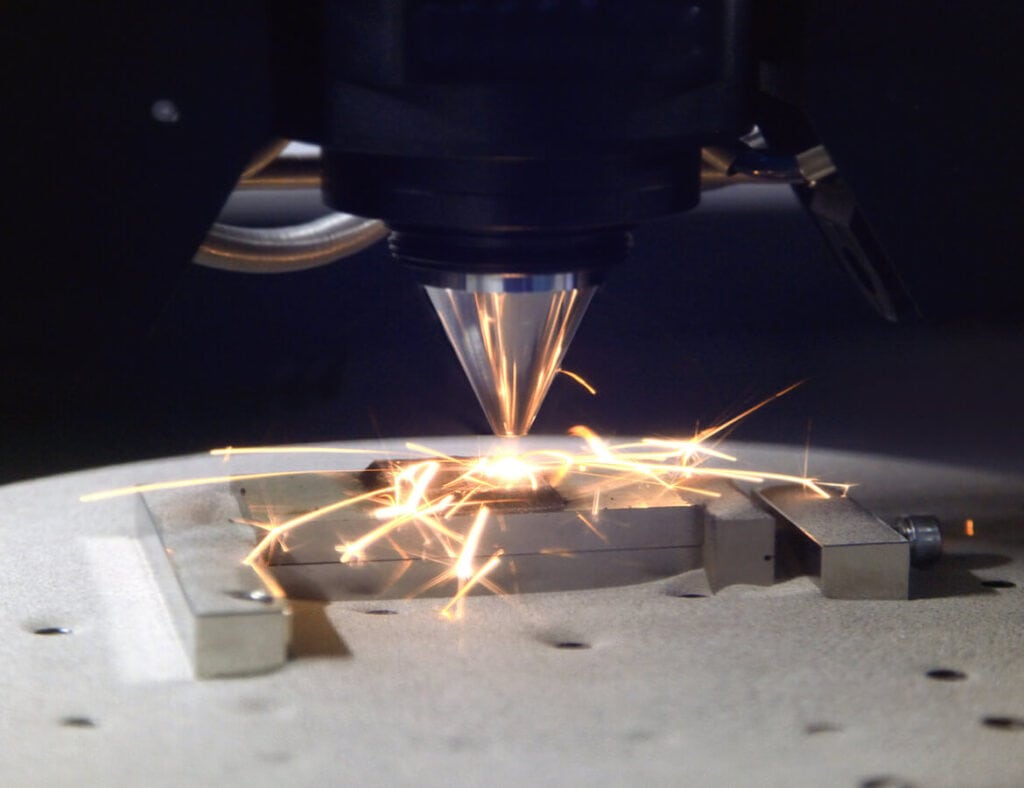

We excel in providing prototype which mirrors the final finished product in look, feel, and functionality. Our prototyping processes combine functionality and manufacturability validation efforts.

Fast Turnaround Time For Prototyping

The conventional prototyping process requires long turnaround time and high costs to produce prototypes due to machines and forming processes’ limitations. Prototypes built in this manner do not have appearance and dimensional tolerances comparable to the final manufactured product.

With the advancement in technology and the invention of 3D printing, prototypes could be easily produced in a short lead time and with a greater degree of complexity.

Our advance prototyping processes combine functionality and manufacturability validation to ensure customers benefit the lowest total costs, fastest time-to-market while maintaining the highest quality standard.

Services

Prototyping by 3D printing enables the prototype to be built faster and it can turnaround more complex product designs.

However, we are able to offer conventional prototyping services depending on your requirements.

- Polyamide with glass fibre filament

- Metal filament

- Carbon fibre mix filament

- PLA

- PVA

- ABS

Why Us

Cost Effective

Our prototyping processes combine functionality and manufacturability validation to ensure customers benefit the lowest total costs.

Prototype Materials

A variety of materials could be selected for 3D prototyping; from standard materials to much more complex materials.

Short Lead Time

With the invention of 3D printing, prototyping could be easily produced in a short lead time and with a greater degree of complexity.

Build prototypes that mirrors the final finished product

while ensuring customers benefit the lowest total costs and highest quality standard.

Our Satisfied Clients Say It Best

K-One is a well-organized company with an abundance of experience in plastic moulding and metal stamping. They are also experienced in box-build and final assembly with products such as electronic headlamps, floor-care machines, and many more. K-One has an extensive supply chain network which enables them to be competitive and efficient from the supply subsystems to integrated end products.

K-One has been our EMS since 2003. It is rare to find a partner that takes proactive measures to continuously improve costs and ensure part quality. K-One has always been by our side and has never taken our business for granted.

We have been working together with K-One for many years, and they have always been very supportive and definitely a pleasure to work with. One aspect that stands out with K-One is that they consistently deliver good quality products.

Talk To Us

Collaborate with us for your next product

HQ/Design Center

+603 7728 1111

+603 7728 6212

66 & 68 Jalan SS22/21

Damansara Jaya

47400 Petaling Jaya

Selangor

Malaysia